4 Key Steps To Successfully creating a Project Control Budget

- Mark Cowley

- Sep 25, 2022

- 8 min read

Updated: Jul 29, 2023

Introduction

Organizations aim for their projects to be successful and to meet client expectations as well as their internal objectives. But what is the reality on the ground?

In a McKinsey article in 2016 their analysis of survey data was summarised as:

" ... Large (construction) projects across asset classes typically take 20 percent longer to finish than scheduled and are up to 80 percent over budget......."

In the foreword to his book Industrial Mega Projects: Concepts, Strategies and Practises for Success, Edward Merrow, Founder and CEO of IPA the foremost project performance benchmarking and consulting organisation states: "Data from more than 300 global megaprojects shows that 65 percent of industrial projects with budgets larger than $1 billion in 2010 U.S. dollars failed to meet business objectives. In some industrial sectors the failure rate was as high as 75 percent. Most of the failed projects were unprofitable, but not all. Some made money due to a serendipitous increase in forecasted product prices or other unanticipated windfalls."

© Merrow, Edward W.. Industrial Megaprojects . Wiley.

(By the way, this book is one of my go-to references for keys to successful project execution)

This is certainly not good news for either owners or project service providers (consultants and contractors) as cost overruns not only destroy business value or impact their margins, but also hinder their ability to execute future projects.

Understanding how to successfully manage project costs is a key and critical part of project management and how to be effective at it can be beneficial for organizations to stay on course as well as set apart successful project leaders from others.

In this blog post, I will look at the four key steps to successfully creating a project control budget. In a future blog post I will look at how to actively manage project costs to the control budget and the benefits and key steps involved in cost management during project execution post baseline agreement with stakeholders.

What is Project Cost Management?

Project cost management is the process of estimating, budgeting and controlling costs throughout the project life cycle, with the objective of keeping expenditures within the approved budget.

For a project to be called successful, it needs to meet these 4 criteria:

it delivers on the functional and/or performance requirements and scope

its execution quality meets the requirements for the delivered facility or scope performs according to specification and the customers needs and expectations

it’s completed on schedule and

it’s completed within budget.

Therefore, project cost management is one of the key pillars of project management and is relevant regardless of the domain, be it manufacturing, retail, technology, construction and so on. During the project planning process one of the steps (see also my blog post and YouTube Video on 5 key steps to successfully creating a Perfect Project Execution Plan. Step 5) is the creation of the project control budget. It creates a financial baseline against which project managers can benchmark the current status of their project costs and adjust the project execution if needed.

Why is a Project Control Budget Important?

The importance of cost management is easy to understand. To take a simple, real-life example, if you decide to build a house, the first thing to do is decided how much you want to spend (your budget). When you have a sense of how much to spend on the project, the next step is to divide the high-level budget into expenses for sub-tasks and smaller line items.

The budget will determine critical decision points such as: which architect or contractor to hire—a high-end one who will construct and deliver the project end-to-end, or someone who can help with a few elements and be able to work for a smaller budget? How many stories should the house have? What quality of materials should be used?

Without a predefined and well-structured project control budget, not only is it difficult to answer these questions, but it becomes impossible to assess whether you are progressing in the right direction to deliver the project on budget once the project is underway.

In large organizations, the scale of this problem is further magnified due to concurrent running of multiple projects, change in initial assumptions and the addition of unexpected costs. The budget is often also determined by the business case based on economic analysis such as an NPV calculation. Ensuring the project stays on track and delivers value is where effective cost management can help.

Then by implementing efficient & effective cost management practices, project managers can:

Get alignment of and set clear expectations with stakeholders

Control scope creep due to a proactive change control established with the project team and the client

Track cost variations and respond with corrective action early

Maintain expected margin, increase ROI (NPV), and avoid losing money on the project

Generate data to benchmark costs for future projects and track long-term cost trends

The Four Key Steps for Successfully creating Project Control Budget

While cost management is viewed as a continuous process, it helps to split the function into five steps: scoping, resource planning, estimation, budgeting and control. During this blog post we will look at the first 4 steps leading to the creation of a project control budget. The overall project cost management steps are mostly sequential, but it’s possible that some scope or resource changes happen midway through the project, forcing the budgets to be adjusted (this should be through a formal change management system). Or, the variances observed during the control process can call for estimate revisions (such as unexpected inflation or productivity loss due to events such as the COVID pandemic).

I will look at each of the four steps in detail.

Step 1: Scoping Not strictly only a project cost management activity but also necessary to understand the scope of the project both in terms of the facility or software, business, etc and the deliverables needed to define and deliver the functionality and performance of the project. It is an essential precursor to 3 project baseline documents:

Project Execution Plan

Project Schedule

Project Control Budget

(see my blog post and YouTube Video on the 5 key steps to successfully creating a Perfect Project Execution Plan for more details of the overall project planning process)

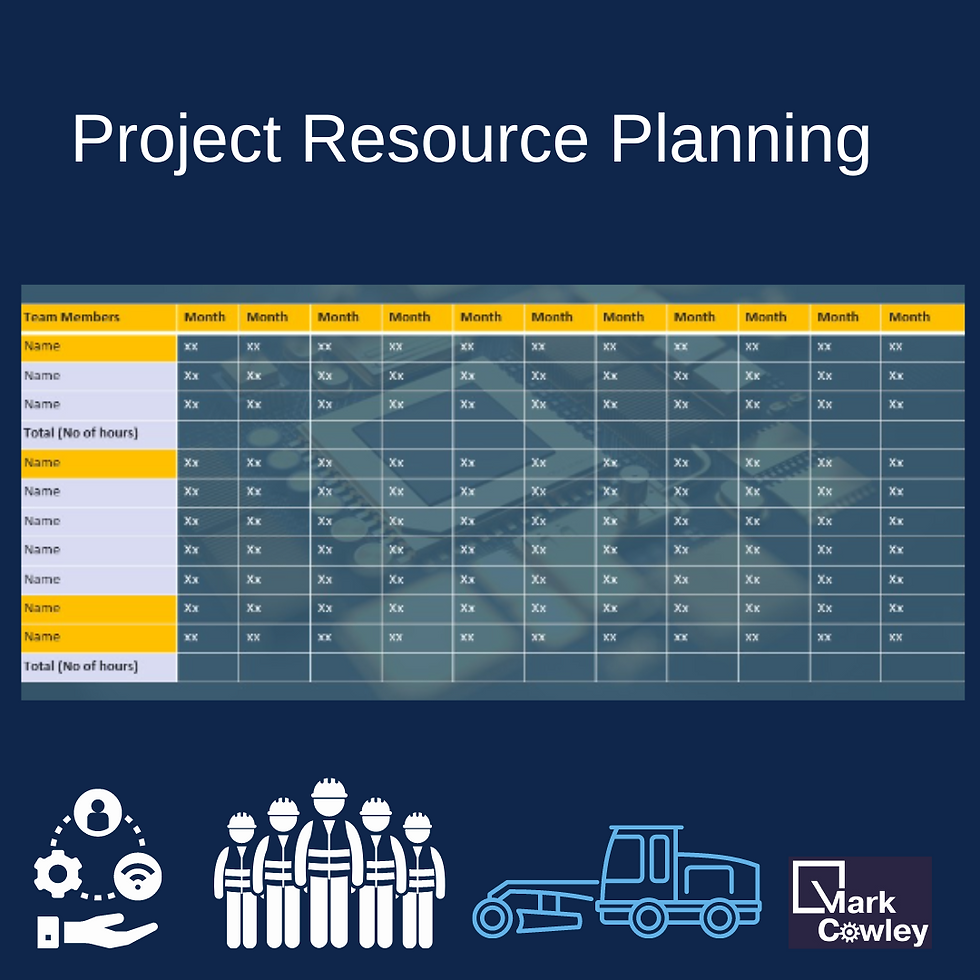

Step 2: Project Resource Planning

Resource planning is the process of identifying the resources required to execute a project and take it to completion. Examples of resources are people (such as staff and construction workers) and equipment (such as infrastructure, large construction vehicles and other specialized equipment in limited supply) and subcontractors.

Resource planning is done at the beginning of a project before any actual work begins and feeds into both project scheduling and cost estimating

To get started, project managers first need to have the work breakdown structure (WBS) ready. They need to look at each subtask in the WBS and ask how many people, what kind of skills are needed to finish this task, and what sort of equipment or material is required to finish this task?

By adopting this task-level approach, it becomes possible for project managers to come up with an accurate and complete list of all resources, which is then fed as input into the next step of estimating costs. A few tips to consider during the process:

Consider historical data—past schedules and effort—before determining sub-tasks and the corresponding resources.

Take feedback from Subject Matter Experts and team members—a collaborative approach works well, especially in projects that do not have past data to use.

Assess the impact of time on resource requirements. For instance, a scarce resource may be available only after a few months, dragging the project’s schedule. This could have an impact on cost estimation.

For large projects, best practice is to determine key resources (such as engineering staff & construction workforce) two ways: (1) through manpower/staffing plans (see illustration above and (2) through resource loading the schedule and then comparing them, resource loading the schedule sometimes (even with smoothing) does not account for continuity requirements for such resources

Although this step happens at the planning stage, project managers need to account for ground realities. For example, you may identify the need for a resource with certain expertise, but if such a resource is not available within the organization, you have to consider hiring a (sub) contractor or training your team to get them up to speed. All these real variables impact cost management.

Step 3: Cost Estimation

Cost estimation is the process of quantifying the costs associated with all the resources required to execute the project.

To perform a detailed cost estimate, the following information is needed:

Resource requirements (output from the previous step)

Price of each resource (e.g., staffing cost per hour, vendor hiring costs, server procurement costs, material rates per unit, etc.)

For bought-out items (equipment, materials, subcontracted services including construction elements) obtaining at least budgetary pricing from vendors and (sub) contractors. For services, this can be either a Lump sum or on a unit rate basis either for manhour effort or quantities (for example $/m3 concrete installed)

The duration that each resource is required

A list of assumptions

Potential risks & opportunities

Past project costs and industry benchmarks, if any

Insight into the company’s financial strength and reporting structures

Estimation is arguably the most difficult of the steps involved in cost management as accuracy is the key here. Also, project leaders and sponsors have to consider factors such as fixed and variable costs, overheads, inflation and the time value of money.

The greater the deviation between estimation and actual costs, the less likely it is for a project to succeed. However, there are many estimation models to choose from. Analogous estimation is a good choice if you have plenty of historical cost data from similar projects. Some organizations prefer mathematical approaches such as parametric modeling (useful during the early stages of projects such as feasibility studies when scope definition is not great enough for analogous estimating) or program evaluation and review technique (PERT).

Then there is the choice between employing a top-down versus bottom-up approach. Top-down typically works when past costing data are available. In this, project managers usually have experience executing similar projects and can therefore take a good call but usually for large projects this is not preferred. Bottom-up works for projects which organizations do not have a lot of experience with, and, therefore, it makes sense to calculate a cost estimate at a task-level and then roll it up to the top (also the usual approach for large projects).

Cost Estimation as a Decision Enabler

It’s useful to remember that cost estimation is done at the planning stage and, therefore, everything is not yet set in stone. In many cases, project teams come up with multiple solutions for a project, and cost estimation helps them decide which way to go. There are many costing methodologies, such as activity-based costing, job costing, and lifecycle costing that help perform this comparative analysis. Also as the scope definition reaches different levels of maturity more accurate estimates with better confidence are developed. The following table shows the American Association of Cost Engineers (AACE) Estimate Classification as typically used in the process industries (oil & gas, chemical, mineral processing...):

Lifecycle costing, for instance, considers the complete end-to-end lifecycle of a project. In IT projects, for example, maintenance costs are often ignored, but lifecycle costing looks long-term and accounts for resource usage until the end of the cycle. Similarly, in manufacturing projects, the goal is to minimize future service costs and replacement charges.

Sometimes the estimation process also allows teams to evaluate and reduce costs. Value engineering, for example, helps to gain the optimal value from a project while bringing costs down.

Step 4: Cost Budgeting

Cost budgeting can be viewed as part of estimation or as its own separate process.

Budgeting is the process of allocating costs to a certain chunk of the project, such as individual tasks or modules, for a specific time period. Budgets include contingency reserves allocated to manage unexpected costs.

For example, let’s say the total costs estimated for a project that runs over three years is $2 million. However, since the budget allocation is a function of time, the project manager decides to consider just the first two quarters for now. They identify the work items to be completed and allocate a budget of, say, $35,000 for this time period, and these work items. The project manager uses the WBS and some of the estimation methods discussed in the previous section to arrive at this number.

Budgeting creates a cost baseline against which we can continue to measure and evaluate the project cost performance. If not for the budget, the total estimated cost would remain an abstract figure, and it would be difficult to measure midway. Evaluation of project performance gives an opportunity to assess how much budget needs to be released for future phases of the project.

Another reason to firm up budgets is that organizations often rely on expected future cash flows for their funding. During the initial phases, the project manager has a limited financial pool and has to set targets accordingly. It’s similar to building the foundation and one floor of the house in the initial few months and later completing the rest of the project, as you save more.

Watch out for my future blog post on managing ongoing project cost to the control budget and how to implement proactive change management to support that process.

Comments